Yantai Sanmon Machinery Equipments Co, Ltd

2019-06-27 09:33 BrowseTimes

API C Series Beam Pumping Unit

API series conventional pumping units are a kind of conventional beam pumping units with crank balance.

They are the most common and most widely used ground power equipment.

Our products completely accord with API Spec 11E Pumping Unit Specification and other related standards

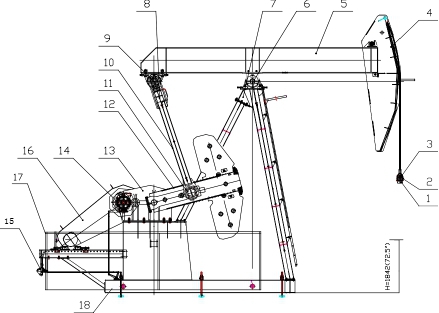

FIGURE.1 PUMPING UNIT STRUCTURE

|

1.Wire Line |

2.Carrier Bar |

3. Polished Rod Slip |

|

4. Horse-head |

5. Walking Beam |

6. Center Bearing Assembly |

|

7. Samson Post |

8. Tail Bearing Assembly |

9. Cross Beam |

|

10. Pitman |

11. Crank Pin Assembly |

12. Crank |

|

13. Gear Reducer |

14. Brake Assembly |

15. Brake handle device |

|

16. Belt Guard |

17. Crank Guard |

18. Base |

Our API series conventional beam pumping units completely accords with API Specification.

Modularization and virtual manufacturing technology have been adopted in the process of designing,

product structure has been optimized, and the parts are of high standardization, universalization,and

serialization.

1. "H" section steel structure, high strength and nice load bearing capacity.

2. Middle width roller center bearing, strong endurance. Self-aligning bearings are adopted in equalizer

beam bearing and crank pin bearing, reducing installation errors and the vibration when pumping unit

is operating.

3. Rack gear is adopted to adjust the crank counterweight, which is very precise and convenient.

4.Hanging structure of the horsehead is"self-abdicating"mechanism , facilitating wellhead operations.

5. Gear reducer adopts herringbone involute or double circular toothed gear, high precision, nice load

bearing capacity, and long service life.

6. Brake adopts internal expanding or external structure. The brake has safety devices, which can brake

quickly, safe and reliable.

7. Lubrication grease is supplied by central lubrication system, reducing manual maintenance.

8. The unit has comprehensive safety protection, the ladder and all moving parts are equipped with

safety guard and safety fences.

Specifications

|

Model |

Rated polished rod load (lbs) |

Stroke length (in) |

Rated torque of reducer (in.lbs) |

|

C-912D-470-240 |

47,000 |

240, 211, 181 |

912,000 |

|

C-912D-427-216 |

42,700 |

216, 185, 155 |

912,000 |

|

C-912D-427-192 |

42,700 |

192, 165, 138 |

912,000 |

|

C-912D-305-192 |

30,500 |

192, 165, 138 |

912,000 |

|

C-912D-365-168 |

36,500 |

168, 144, 121 |

912,000 |

|

C-912D-305-168 |

30,500 |

168, 144, 121 |

912,000 |

|

C-912D-427-144 |

42,700 |

144, 123, 102 |

912,000 |

|

C-640D-305-192 |

30,500 |

192, 165, 138 |

640,000 |

|

C-640D-305-168 |

30,500 |

168, 144, 121 |

640,000 |

|

C-640D-365-144 |

36,500 |

144, 123, 102 |

640,000 |

|

C-640D-305-144 |

30,500 |

144, 123, 102 |

640,000 |

|

C-640D-256-144 |

25,600 |

144, 123, 102 |

640,000 |

|

C-640D-305-120 |

30,500 |

120, 102, 84 |

640,000 |

|

C-456D-305-168 |

30,500 |

168, 144, 121 |

456,000 |

|

C-456D-305-144 |

30,500 |

144, 123, 102 |

456,000 |

|

C-456D-256-144 |

25,600 |

144, 123, 102 |

456,000 |

|

C-456D-365-120 |

36,500 |

120, 102, 84 |

456,000 |

|

C-456D-305-120 |

30,500 |

120, 102, 84 |

456,000 |

|

C-456D-256-120 |

25,600 |

120, 102, 84 |

456,000 |

|

C-320D-256-144 |

25,600 |

144, 123, 102 |

320,000 |

|

C-320D-256-120 |

25,600 |

120, 102, 84 |

320,000 |

|

C-320D-213-120 |

21,300 |

120, 102, 84 |

320,000 |

|

C-320D-305-100 |

30,500 |

100, 85, 70 |

320,000 |