It is mainly used to solve the problem of irrational stroke frequency in pumping unit operation. At present, the stroke frequency adjustment is finished relying on experience. The up stroke speed and down stroke speed of polished rod can't be adjusted separately. The maximum potential of well and pumping unit can't be fully brought out.

The intelligent control system could adjust the up stroke and down stroke speeds separately according to the actual operation condition of pumping unit. When the polished rod goes downwards, the control system maximizes the down stroke speed of polished rod under the precondition that neither the polished rod falls off nor the motor and gear reducer work overload. When the polished rod goes upwards, the control system maximizes the up stroke speed of polished rod under the precondition that the polished rod works overload but the motor and gear reducer don't work overload. This makes the stroke frequency of pumping unit match with the working condition, to increase the production.

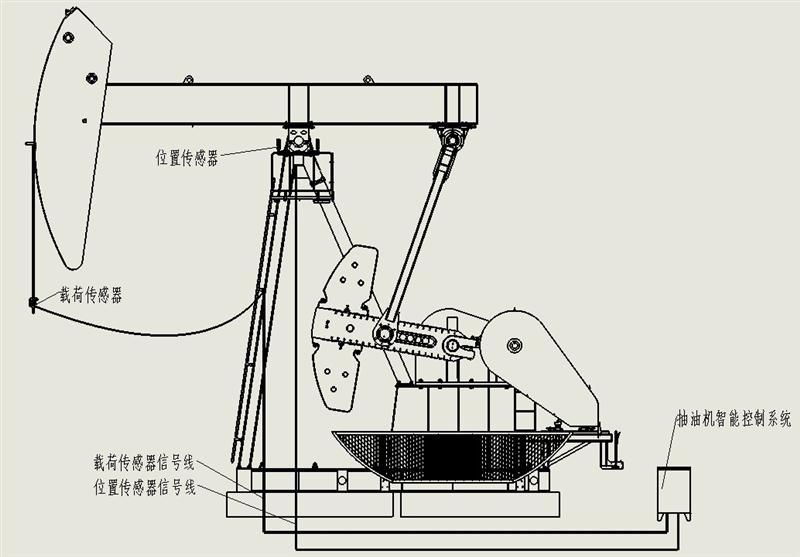

Add a position sensor at center bearing assembly position to judge the up stroke and down stroke of polished rod.

Add a load sensor on the carrier bar to test the indicator diagram and to ensure the polished rod doesn't fall off during down stroke and doesn't work overload during up stroke.

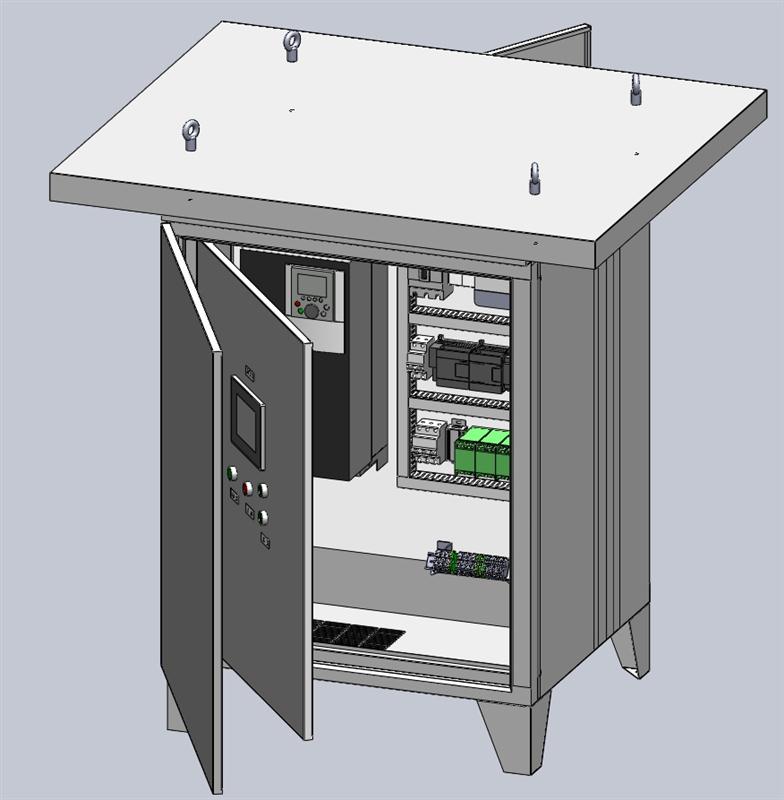

1) As for the pumping unit with frequency conversion control system, just add an intelligent control module to fulfill intelligent control.

2)As for the pumping unit with no frequency conversion control system, install the intelligent control module with frequency converter to fulfill intelligent control.

1)Voltage and frequency: user specified

2)Power: user specified

3)Ambient temperature: -40℃—+50℃

4)Altitude: 3000m below

5)Relative humidity: 95% below (no dew)

6)Protection level: IP54

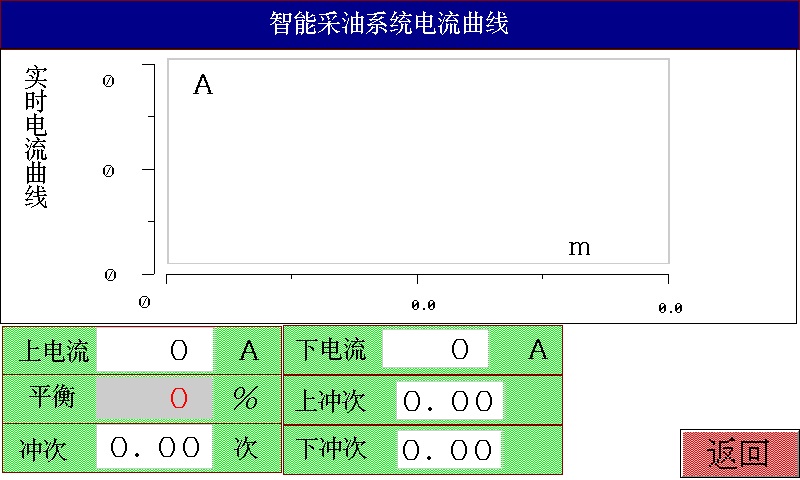

We here mainly show the Home interface for operation as below

The interface for operation can be supply in English or other language as per requirements, now just take an example of a Chinese interface for operation.

1) Model of pumping unit

2) Allowed maximum and minimum stroke frequency of pumping unit

3) Voltage and power of motor

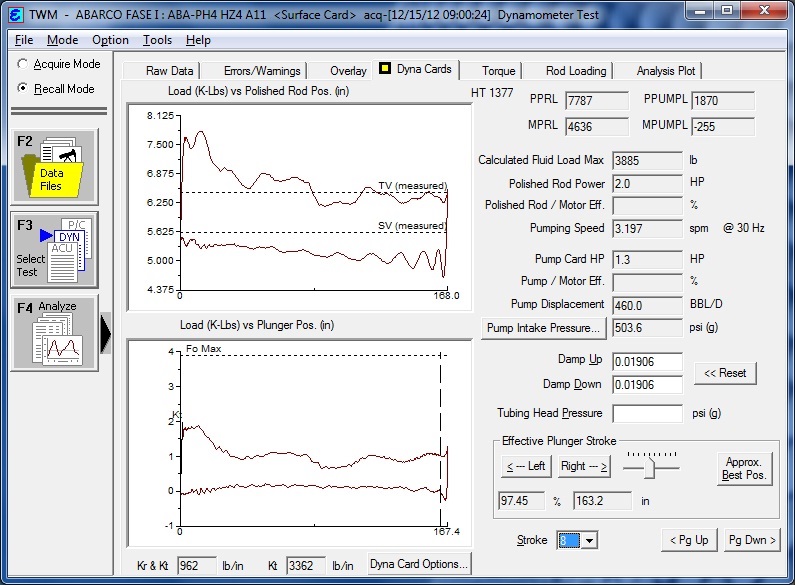

Oil field of Sinopec in Colombia

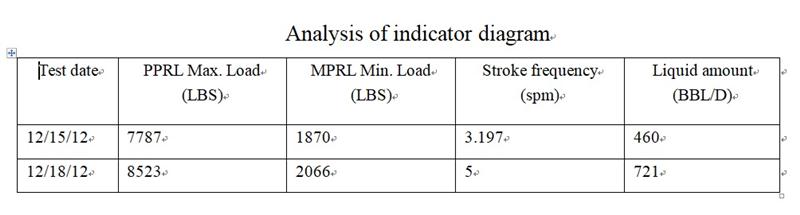

Indicator diagram before installing intelligent control system

Indicator diagram after installing intelligent control system

The stroke frequency is improved by 1.8spm (56%) and the liquid amount is improved by 261 BBL/D (56.7%) after installing intelligent control module.